"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

01/28/2016 at 09:53 • Filed to: mustang

1

1

9

9

"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

"Jake - Has Bad Luck So You Don't Have To" (murdersofa)

01/28/2016 at 09:53 • Filed to: mustang |  1 1

|  9 9 |

The more I dig into this Mustang, the less I appreciate Ford’s engineering choices. Let’s take a look at the assembly for the convertible top on my ‘05 Mustang V6.

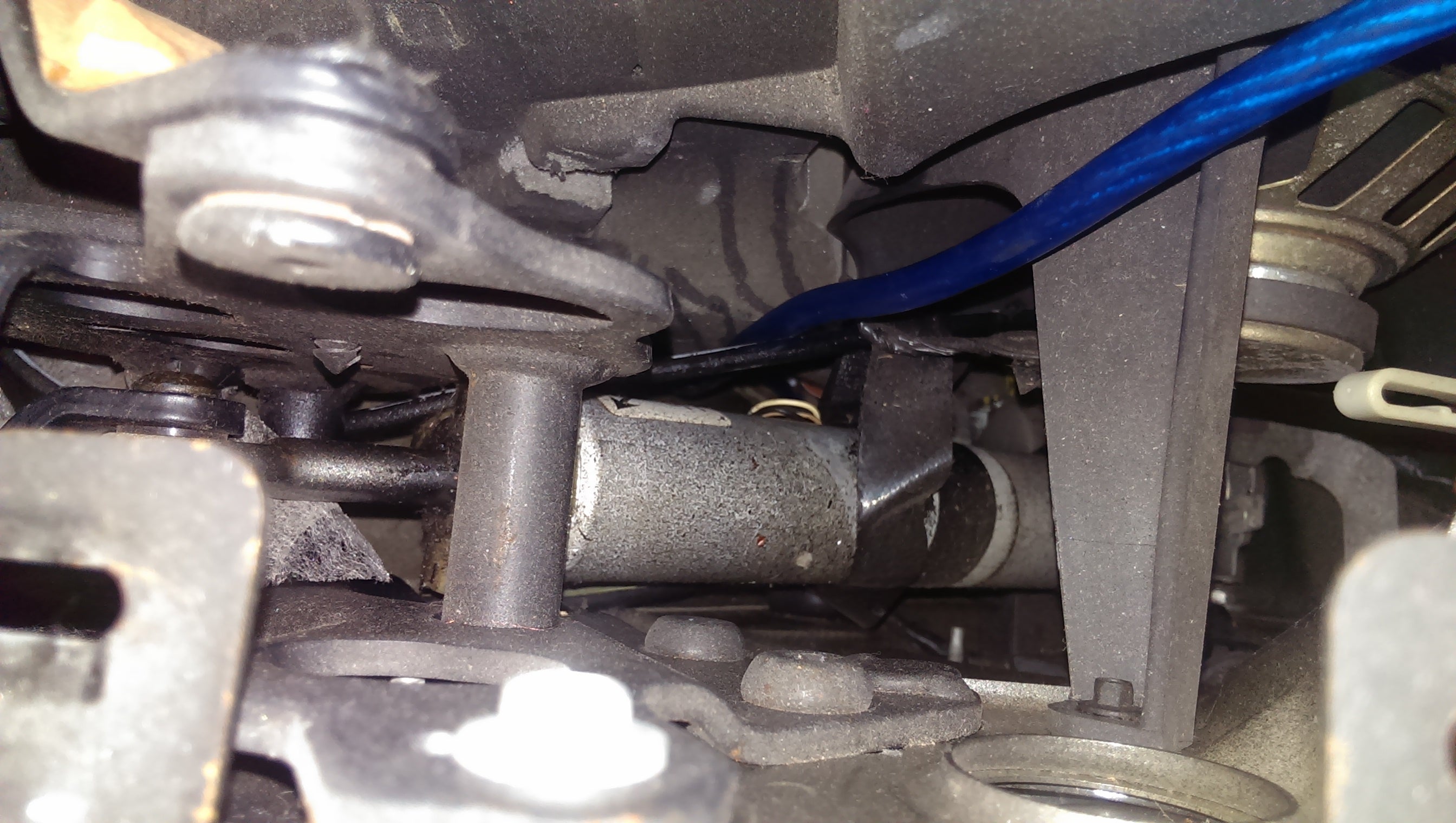

Oh, neat. A hydraulic system. That’s much nicer than a pair of motors and a gearbox directly connected to the top. The problem in this picture is that the cylinder should be up and to the left about 2 inches. Right here it’s resting on the passenger seat belt retractor, hidden from view on the right. What Ford did to mount the cylinder was put two holes about 1/2 inch deep on either side of the cylinder, towards the top of it. The outboard one fits onto a smooth greased stud on the body (hidden from view, bottom-ish of the picture) and the inboard side is held in with a stud attached to a chunk of metal held in place by one screw. One little bitty screw with no loctite. Wanna guess where this is going? Over the life of the car that screw came loose, go figure, and sent the cylinder smashing into my passenger seat belt restraint system, fucking up the retractor so now it doesn’t retract all the way. Fortunately I found the pieces hiding on the bottom of the floor pan and got it mended. Top works beautifully now, which is nice because we are in for some beautiful weather this weekend in Kansas.

Also, convertibles always look better with the top down.

I also got most of the wiring in place for a small subwoofer and amp to sit in the trunk. The interior of this car is held together entirely with plastic snaps, and comes apart if you look at it right, which is a blessing and a curse. My luck continues to prevail, as there was a perfect-sized grommet for my 4-gauge wire unused in the firewall. Poke a hole through that and the sound deadening/insulation and I’m good to go. All that’s left to do now is strip the wires, crimp on the connectors, and hook the whole mess up now that the wires are run, and enjoy. But first I’m having the car professionally detailed, since it was a bit of a messy disaster when I got it.

RamblinRover Luxury-Yacht

> Jake - Has Bad Luck So You Don't Have To

RamblinRover Luxury-Yacht

> Jake - Has Bad Luck So You Don't Have To

01/28/2016 at 10:04 |

|

May I refer you to my rule of thumb: Of the big three, GM prefers overly simple solutions with little forethought that come back to bite them in the ass. Ford prefers (jazz hands) “WACKY!” solutions to things that are more “clever” than effective, and which are not engineered well enough to prevent being bitten in the ass. Chrysler attempts to implement clever solutions in the most simple (read, cheap) and sometimes stupid way. So the end result is, GM is dumb, Ford is crazy, and Chrysler is an unpredictable mix of both.

Jake - Has Bad Luck So You Don't Have To

> RamblinRover Luxury-Yacht

Jake - Has Bad Luck So You Don't Have To

> RamblinRover Luxury-Yacht

01/28/2016 at 10:10 |

|

Also: Ford engineers have a Torx fetish. I appreciate this very much.

Slant6

> Jake - Has Bad Luck So You Don't Have To

Slant6

> Jake - Has Bad Luck So You Don't Have To

01/28/2016 at 10:11 |

|

I’ll take a geared top system over a hydraulic one any day. It’s so messy and expensive to work on.

My old Saab convertible never worked correctly. Eventually just wired in a switch to release the tonneau to open and kept the hydraulic pressure released.

RamblinRover Luxury-Yacht

> Jake - Has Bad Luck So You Don't Have To

RamblinRover Luxury-Yacht

> Jake - Has Bad Luck So You Don't Have To

01/28/2016 at 10:12 |

|

It comes from that “clever” thing. They took a hard accidental blow to the head while eating a Bismarck, and now they’re addled *and* think they’re German.

Jake - Has Bad Luck So You Don't Have To

> Slant6

Jake - Has Bad Luck So You Don't Have To

> Slant6

01/28/2016 at 10:15 |

|

The problems with gear systems are slop. Once you get past a point of equilibrium the top stops pulling one way on the gears and starts pushing another (Because gravity). Any slop in the system results in the top ‘falling’ in that direction for a little before getting arrested by the gears. This puts ridiculous strain on all of the gears, and doesn’t look very nice either.

Also I can buy an entire new hydraulic system for $300. A new cylinder is $120. And the whole mess only has one motor to worry about. I thought hydraulic tops were stupid at first but it’s really easy to work on and goes up and down faaar smoother than the geared systems I’ve used (Chrysler PT Cruiser and Sebring convertible used gears, I believe).

Jake - Has Bad Luck So You Don't Have To

> RamblinRover Luxury-Yacht

Jake - Has Bad Luck So You Don't Have To

> RamblinRover Luxury-Yacht

01/28/2016 at 10:16 |

|

Meanwhile at GM...

“METRIC”

“NO, IMPERAL”

“NO, USE TORX FOR EVERYTHING”

The end result is that I need three types of socket to work on my goddamn LeSabre.

Future next gen S2000 owner

> Jake - Has Bad Luck So You Don't Have To

Future next gen S2000 owner

> Jake - Has Bad Luck So You Don't Have To

01/28/2016 at 10:42 |

|

I used to have a lock lug nut on my wheels. I realized no one is stealing my ten year old wheels, so I had the dealership replace them. I now have 4 lug nuts that are 13/16" and one that is a 22mm or 21mm - can’t remember which one it is - one all four wheels.

MasterMario - Keeper of the V8s

> RamblinRover Luxury-Yacht

MasterMario - Keeper of the V8s

> RamblinRover Luxury-Yacht

01/28/2016 at 11:19 |

|

I have been learning that about Ford with my truck...need to replace a rotor because of a frozen caliper? Have fun, because you need to remove the entire hub to do that.

RamblinRover Luxury-Yacht

> MasterMario - Keeper of the V8s

RamblinRover Luxury-Yacht

> MasterMario - Keeper of the V8s

01/28/2016 at 11:37 |

|

That’s Ford Perversity Permutation 6, Subcategory A: Early adoption of advanced technology, before it has matured, and then iterating that instead of ever, ever replacing it outright. See also Twin I-Beam. Not to be confused with Perversity 8, which is “Keep Changing This Bad Solution Until We Find One That Mostly Works By Accident” - see 80s F-series fuel injection.

In this case, they started making a special version of their normal drum hubs back in the 60s that just happened to have a disc on the outside so they could have disc brakes without needing a different machining process on the main part of the hub, just an extra step to finish the rotor part. That worked well enough that they used it on everything far beyond the point at which it made sense.

The GM version of that hub bad idea was to use their normal drum brake hub with different holes in it, and to have studs pressed into the hub from the back holding the rotor onto the back. So, you don’t have to replace the hub casing every time, but it takes even more time and special tools to take apart. And it’s really heavy for what it is.And then they left the rotor much too small for the job. DURRRRR